Introduction

Aluminium easy peel off end lid top for food cans are typically coated on aluminum sheets rather than coils. Clear lacquer aluminum foil sheet for easy peel off foil end lid top coatings are applied by direct-roll coaters similar to those used in sheet coating operations for 3-piece can bodies, and some facilities use the same coating lines to coat can bodies and ends. Because both the interior and exterior surfaces are usually coated, each sheet is subjected to two separate application and drying steps. If UV-cured exterior coatings are used, these coatings are applied first. The UV coating is set by passing the sheets under a bank of UV drying lamps. Clear lacquer Aluminum foils sheets are then collected and turned over by wickets in preparation for the interior coating application, which is applied by a direct-roll coater. The sheets then pass through a drying oven to cure the interior coatings and complete the cure of the exterior UV-cured coating. Can ends are then formed in processes similar to those used to produce aluminum beverage can ends. The end seal compound application step is also similar to that used in aluminum beverage can manufacturing.

Sheet-coated easy peel off foil end lid top require additional fabrication steps such as when the metal is scored and when a tab is attached. These steps are performed after the end piece has been coated and therefore damage the coating. Repair coatings are applied after these steps to restore the integrity of the coatings.

Combining the metal can with other materials such as plastic or foils can create an entirely new image. Cans for powdered milk, for example, have an aluminium foil tagger sealed on the closure ring conferring pilfer resistance and easy opening as well as an impression of hygiene. Plastic lids fitted over normal end seams and used for re-closure after opening are both decorative and functional.

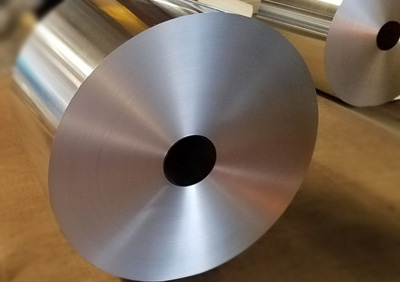

We supply pure aluminium foil, either with a clear, protective lacquer coating or with a heat-seal lacquer coating, in thicknesses from 0.060 to 0.120 mm.

We supply pure aluminium foil, either with a clear, protective lacquer coating or with a heat-seal lacquer coating, in thicknesses from 0.060 to 0.120 mm.